Context

-

My senior capstone project at Olin College towards a Bachelor’s in electrical and computer engineering.

- Work on the project took place over a full academic year in a team of three mechanical engineering students and two (including myself) electrical and computer engineering students.

-

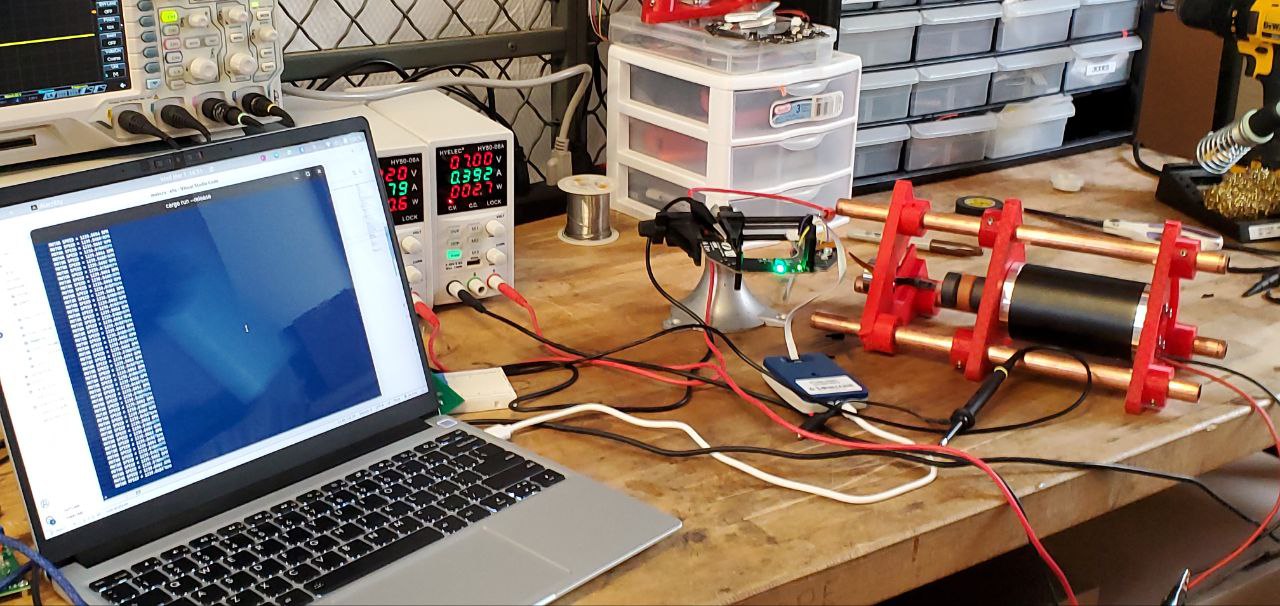

We delivered a documented, tested prototype for a compact energy harvesting system on behalf of Watts Water through Olin’s SCOPE program.

- The goal for the project was to harvest energy from the pressure drop between the municipal water supply and the home water system.

- The implementation consisted of a high-pressure flow chamber containing a turbine attached to an actively-controlled regenerative braking system.

Responsibilities

Sole

- The regenerative braking firmware implementation, including electrically modeling the turbine/motor system and controlling the motor to extract power.

- In my role as the team’s business manager, procuring raw materials, test boards, electrical component orders, manufacturing, and other miscellaneous items.

Shared

- With our other electrical engineer, for block-level system design, component selection and testing using development boards.

- Also with our other EE, testing our manufactured PCB and our full electromechanical system. Before we had a finished mechanical system or testbench, this required some creativity.

Skills

- Rust

- We wrote our firmware in Rust, partially for its robust embedded support and partially as an educational opportunity.

- I got comfortable using Rust’s

#![no_std]environment, as well as thecargotoolchain management and easy flashing.

- STMF3

- We used an STMF303 microcontroller as the brains of our application’s PCB, because of its motor controller support and ADCs.

- Towards the end of the development cycle, we recommended an STML4-series microcontroller due to its lower power consumption and highly-efficient standby modes.

- Power Electronics

- I used the Piecewise-Linear Electrical Circuit Simulation (PLECS) software to model the motor control aspects of our system because of its efficient switching simulation.

- I successfully adapted the 3-phase brushless DC motor into a power turbine capable of extracting up to 0.5 watts in normal operating conditions.

- Communication

- We had weekly progress meetings with our Watts handler, Joe Burke, as well as several design reviews and presentations during the course of the academic year.

- Extensive technical documentation was a significant part of our final deliverable, as well, as the project was picked up by Watts engineers after our year ended.

- Teamwork

- We had the same team of five across the whole year, which meant communicating interpersonally to ensure we were all working in the same direction.

- It also meant selecting and using appropriate project management tools. We used Notion.